Compounding Solutions

With decades of expertise, FL Pipe provides custom compounding solutions using recycled materials and industrial side streams, designed to meet your exact specifications and sustainability objectives.

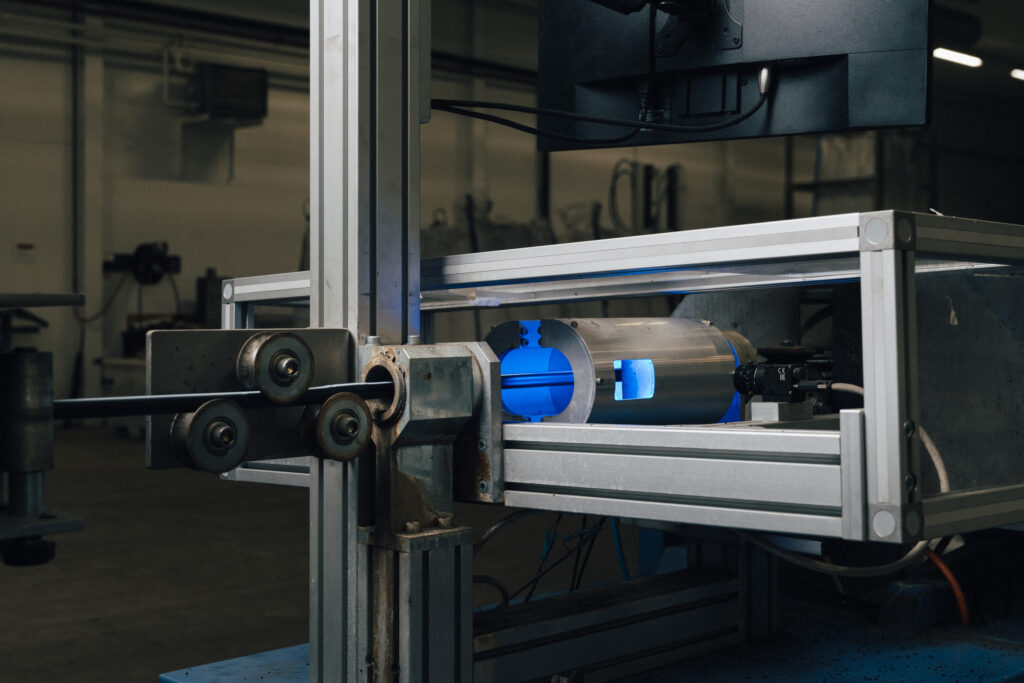

Our Compounding Capabilities

FL Pipe specializes in transforming industrial waste into high-quality compounded materials. By incorporating recycled raw materials and customized additives, we tailor our process to meet each client’s unique needs.

Wide Range of Additives and Fillers

Select from colorants, stabilizers, plasticizers, and more to achieve the exact properties required for your application.

Expertise in Diverse Polymers

We specialize in PP, PE, PLA, PBS and other polymers, creating the ideal blend to suit all your applications.

Material Customization

Tailored formulations using recycled materials and industrial side streams to meet your specific requirements.

Here’s how it woks

Recipe Development

The compounding process starts with either the customer’s own recipe or FL Pipe’s proprietary recipe base, which is then refined to meet the project’s specific requirements. This ensures a customized approach that aligns perfectly with the intended application.

Customization and Blending

Our technicians expertly blend high-quality recycled polymers with carefully selected additives and fillers, including stabilizers, colorants, and plasticizers. This step is fully tailored to achieve the desired material properties, such as durability, flexibility, and thermal resistance.

Testing and Validation

A test batch is produced and undergoes thorough quality assurance checks in our state-of-the-art laboratory. If necessary, adjustments are made to fine-tune the material’s performance and ensure it meets the client’s specifications.

Final Product

Once validated, the compounded material is produced at full scale and delivered ready for use in your production process. This ensures a reliable, high-performance product tailored to your specific needs.

Custom Formulations – Tailored to Your Needs

We understand that every industry has unique material requirements, which is why we offer customized compounding solutions to meet specific performance needs. Our expertise in material science allows us to:

Develop tailor-made compounds using PP, PE, PLA and PBS

Adjust mechanical properties, flexibility, and strength to suit various applications

Ensure consistent quality and performance across all production batches

Certified Quality to Ensure Consistency and Reliability

FL Pipe adheres to strict international and Nordic quality standards, guaranteeing durability, safety, and performance across all products

ISO 9001 Certification – Ensures rigorous quality control at every stage of production.

ISO 14001 Certification – Demonstrates our commitment to sustainable and eco-friendly operations.

Nordic Poly Mark Certification – Confirms compliance with high durability and climate resilience standardsfor Nordic infrastructure.

Advanced Laboratory Testing – Guarantees consistent material strength, purity, and performance.

Ready to Create Custom, Sustainable Materials with FL Pipe?

Our team is ready to collaborate on compounding projects tailored to your exact specifications, from product development to large-scale production. Partner with us to achieve your sustainability goals and create innovative, durable materials using recycled and industrial side streams.

Applications of Compounded Materials

Construction

Durable, custom materials designed for piping, insulation, and infrastructure applications.

Packaging

Eco-friendly compounds for packaging, designed to meet both quality and sustainability standards.

Agriculture

Compounded materials for durable agricultural products, including irrigation systems and greenhouse films.

Manufacturing

High-strength materials for parts and components, customized to meet specific industry requirements.

FAQ

Custom compounding is the process of blending recycled polymers with additives and fillers to create tailored materials for specific applications.

Yes, we can use your recipe or develop one based on our proprietary formulations to meet your exact specifications.

We work with PP, PE, PLA, PBS and other polymers to create blends optimized for your needs.

We produce test batches, conduct rigorous quality assurance checks, and adjust formulations as needed to deliver high-performance materials.